Roofing Material Calculator

Calculate your roof’s size and estimate how many bundles of shingles, rolls of felt, and squares of roofing material you need for a new roof. Add the price per square for materials to get an estimated material cost.

-

By

FindPros

FindPros connects consumers with professionals in over 600 different categories.

-

Reviewed by

Jacky L.

FindPros connects consumers with professionals in over 600 different categories.

Dimensions measured from the ground

Roofing Material Estimate:

Estimated Material Cost

Installation Overview

How to Estimate the Size of a Roof

If you’re replacing a roof, one of the first considerations you make needs to be the roof’s size so you can accurately estimate project materials.

In the US, roofs are measured in square footage, and roofing contractors typically quote projects based on the size of the roof in squares, which are equal to 100 sq. ft. If your roof measures 2,300 sq. ft, then you would need 23 squares of material.

Consequently, gathering the size of the roof in squares and square footage is the first step.

Keep in mind that there is no correlation between the size or square footage of your home and that of your roof. A 2,000 sq. ft. home may have a simple gable roof, a complex cross-gable roof, or a hipped roof, and each one of these roofs will have a different size to them.

Typically, the more slopes your roof has, the higher the total square footage will be. For example, a gable roof has two slopes, so it needs less material than a Dutch roof, which has three slopes, or a hipped roof, which has four. This is true even if the footprint and size of the home itself are identical in each case.

Find the Area of the Footprint of the Roof

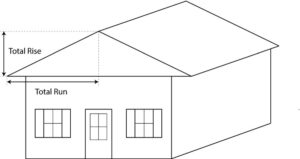

To calculate a roof’s dimensions, you need to measure the roof as if it were flat, then account for roof pitch, calculate square footage, and finally determine how many squares of material are required for the roof.

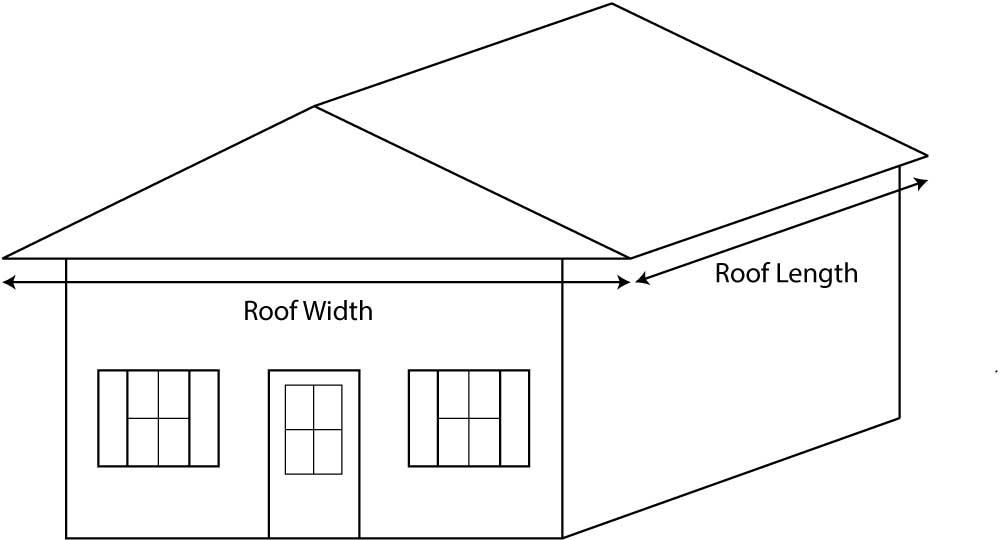

Keep in mind that you will need to do this for each section of the roof. While the illustration above shows a simple gable roof, a cross gable roof will require you to take the length and width of each individual section, and complex roofs like gambrels and mansards will have two sections of roofing to each side.

The calculator above can handle all of this; simply enter the length, width, and pitch, and it will determine the size of the roof in squares.

Start by measuring the roof’s length and width in feet as you’re standing on the ground. Remember that the length and width need to be found for the roof, not the house, so take into account that the roof overhangs the building.

Then determine the area of the roof as if it were flat. Multiply the length by the width in feet to get the area measurement.

Finding the Total Roof Area

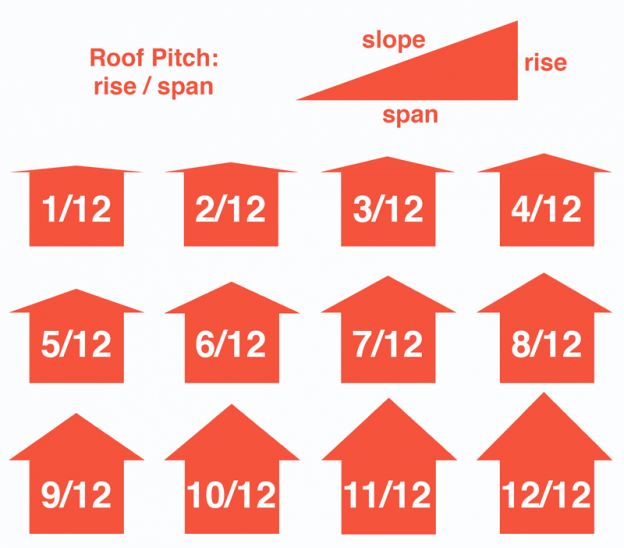

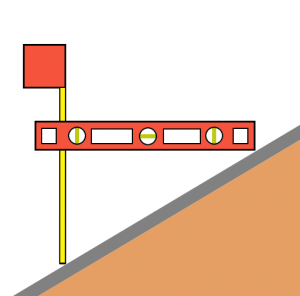

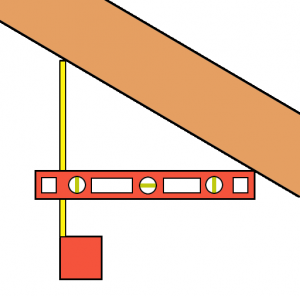

Once the area of the roof’s footprint is known, the overall roof area can be found by accounting for the roof’s pitch. The pitch of the roof is the rise over a 12-inch run.

This means that for every 12 inches horizontally, your roof will rise a specific number of inches. Most roofs will fall between a rise of 4/12 and 8/12, but a gambrel roof will likely have a section that is 20/12 and a section that is 7/12. This can mean that you need to calculate for each area separately.

It’s also important to keep in mind that each section of roofing may have its own pitch. This is true even of gable roofs, which may be what is known as a dual-pitch gable – one side of the roof will have a different pitch than the other side. You will need to calculate each side separately in this case.

Use our roof pitch calculator to find the pitch of your roof.

Next, multiply the footprint of the roof by the multiplier below for your roof pitch to find the overall roof area.

For example, a 4/12 pitch roof that is 100 square feet:

Roof Pitch Area Multipliers

Multipliers for common roof pitches that can be used to find the total area of a roof.

| Pitch | Multiplier |

|---|---|

| 0/12 | 1 |

| 1/12 | 1.0035 |

| 2/12 | 1.0138 |

| 3/12 | 1.0308 |

| 4/12 | 1.0541 |

| 5/12 | 1.0833 |

| 6/12 | 1.118 |

| 7/12 | 1.1577 |

| 8/12 | 1.2019 |

| 9/12 | 1.25 |

| 10/12 | 1.3017 |

| 11/12 | 1.3566 |

| 12/12 | 1.4142 |

| 13/12 | 1.4743 |

| 14/12 | 1.5366 |

| 15/12 | 1.6008 |

| 16/12 | 1.6667 |

| 17/12 | 1.7341 |

| 18/12 | 1.8028 |

| 19/12 | 1.8727 |

| 20/12 | 1.9437 |

| 21/12 | 2.0156 |

| 22/12 | 2.0883 |

| 23/12 | 2.1619 |

| 24/12 | 2.2361 |

Finding the Size of the Roof in Squares

Roofing contractors estimate projects and materials by the square, so it is crucial to find this measurement to estimate the amount of material needed accurately. A square simply refers to a 10′ x 10′ square of roofing. This is simply 100 square feet of roof.

To find the squares, divide the overall roof area by 100 and then round up. For instance, if the roof is 1550 square feet, then it is 16 squares.

How to Estimate Roofing Materials

Although roofing projects are estimated and sold by the square, roofing material is often not sold in 1-square increments.

How Many Bundles of Shingles Will You Need

The average bundle of shingles covers 33.3 sq. ft., so three bundles of shingles are needed per square. Asphalt shingles range in price from about $25 per bundle for a standard 3-tab style to around $50-$75 or more for an upgraded architectural style.

Since transportation is a major cost factor, expect prices to vary by location. A typical bundle of shingles weighs about 75 pounds, while some premium products can weigh over 100 pounds per bundle, so consider delivery of materials.

Typically, only asphalt shingles are sold by the bundle in this way. Roofing shingles can come in other materials, including wood, metal, plastic, and slate, and that each of these materials may be packaged and sold in other ways.

How Many Rolls of Felt Will You Need

Roofing felt is sold by the roll. The average roll of 15-pound roofing felt covers about 400 sq. ft., or 4 squares, while the average roll of 30-pound roofing felt covers about 200 sq. ft. or 2 squares.

Rolls of felt are 36″ wide x 144′ long for 15# and 72′ long for 30#. Consider other underlayment options as needed, such as ice and water shield, rubber, or tar products.

The felt that your roof needs will be dictated by the roofing material. 30-pound felt is the most common and recommended type for most roofs, but a tile roof often requires 50-pound. In addition, new synthetic materials are also available, which are thinner and lighter weight while having superior performance.

Always check to see what is recommended by the manufacturer of the roofing material you are installing, or check with your roofer.

How Many Nails Will You Need

Nails will also be required for most roofing projects. The average 3-tab shingle needs four nails per shingle. High-wind areas and other types of shingles may need more. You’ll typically need 320 nails to install a square of standard 3-tab shingles, assuming four nails per shingle and 80 shingles per square.

However, architectural shingles may require 480 nails per shingle. Materials like tile, slate, and some types of metal roofing may use other fasteners as well.

Standing seam roofs, for example, do not use nails but have hidden fasteners in the seams. Always consult the manufacturer for the material you are choosing to use on your roof for the recommended fasteners and number required per square.

Other Materials

Keep in mind that a drip-edge will be needed to protect the roof’s edge from rot, vents, and other materials such as flashing or caulk. Also, consider that the fascia boards may need to be replaced depending on their condition.

Drip-edge and fascia boards are sold by the linear foot, find the perimeter of your roof in feet to find the length of drip-edge and fascia boards needed.

In addition to accurately estimating materials, it is important to make sure you order extra material when ordering. Account for about 5-10% overage on your project to make sure you have enough material if measurements are a little off or material is wasted or damaged. This is more critical for materials that are special-order or have long lead times.

We recommend getting free roofing estimates to understand material and labor costs and identify other project complexities that could affect the cost.

Other Considerations

There are some other factors to consider when installing a new roof. Learn about the costs of installing a new roof. Many localities require permits and inspections for roofing projects; check with your local inspections office and consult local building codes for more information on the requirements.

Also, consider that removing old materials is often required and will require disposing of a large amount of waste. Plan ahead for this by ordering a dumpster for the project.

Think your home might be due for a new roof? Learn the warning signs that it’s time to replace it before it leaks.