Rebar Weight and Size Calculator

Calculate the weight and size of the rebar for your project given the length and quantity.

-

By

FindPros

FindPros connects consumers with professionals in over 600 different categories.

-

Reviewed by

Jacky L.

FindPros connects consumers with professionals in over 600 different categories.

Results:

Total Weight

Total Length

Pounds per Foot

Kilograms per Meter

How to Find the Size and Weight of Rebar

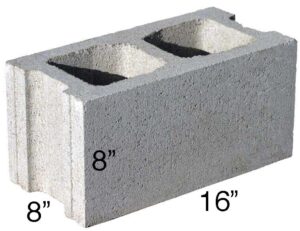

Rebar, or reinforcing bar, is used in many masonry and concrete projects to reinforce slabs and structures. Because concrete has low compressive strength, rebar helps it bear loads without cracking.

Therefore, for most concrete projects, rebar is required to help the slab, footer, or foundation maintain its structural integrity. Rebar is available in standard sizes, making it easy to find the weight and dimensions of the rebar for your project.

The first step is to identify which size of rebar is being used on the project, for example, a #3 rebar. Most home and residential projects will use #3, #4 or #5 rebar, with #3 being used most commonly for patios and driveways, #4 for walls and columns, and #5 for footers and foundations.

The next step is to identify how much linear footage of rebar will be used. Linear footage is the total amount of length in 12″ increments needed for the project.

For example, if you need 20 pieces of 60′ rebar, you will need 1,200 linear feet of material. Rebar is typically sold in 20′, 30′, 40′, and 60′ lengths, but it is possible to order custom lengths as well.

You can use our rebar material calculator to find out how much rebar you need for your project. Alternatively, multiply the length of rebar by the quantity used to find the linear footage. Learn more about how to find linear footage.

Refer to the charts below for the dimensions for each size of rebar. Find the diameter and area of the rebar along with the weight per linear foot. To find the total weight, multiply the total length of rebar – total linear feet of material used – with the weight per linear foot if measured in feet, or weight per meter if measured in meters.

How to Find the Size and Weight of Rebar

Rebar, or reinforcing bar, is used in many masonry and concrete projects to reinforce slabs and structures. Because concrete has low compressive strength, rebar helps it bear loads without cracking.

Therefore, for most concrete projects, rebar is required to help the slab, footer, or foundation maintain its structural integrity. Rebar is available in standard sizes, making it easy to find the weight and dimensions of the rebar for your project.

The first step is to identify which size of rebar is being used on the project, for example, a #3 rebar. Most home and residential projects will use #3, #4 or #5 rebar, with #3 being used most commonly for patios and driveways, #4 for walls and columns, and #5 for footers and foundations.

The next step is to identify how much linear footage of rebar will be used. Linear footage is the total amount of length in 12″ increments needed for the project.

For example, if you need 20 pieces of 60′ rebar, you will need 1,200 linear feet of material. Rebar is typically sold in 20′, 30′, 40′, and 60′ lengths, but it is possible to order custom lengths as well.

You can use our rebar material calculator to find out how much rebar you need for your project. Alternatively, multiply the length of rebar by the quantity used to find the linear footage. Learn more about how to find linear footage.

Refer to the charts below for the dimensions for each size of rebar. Find the diameter and area of the rebar along with the weight per linear foot. To find the total weight, multiply the total length of rebar – total linear feet of material used – with the weight per linear foot if measured in feet, or weight per meter if measured in meters.

US Rebar Weight and Dimensions

US rebar sizes and dimensions

| Imperial Bar Size | “Soft” Metric Size | Weight | Nominal Diameter | Nominal Area | |||

|---|---|---|---|---|---|---|---|

| lb/ft | kg/m | inch | mm | inch2 | mm2 | ||

| #2 | #6 | 0.167 | 0.249 | 0.250 = 1/4“ | 6.35 | 0.05 | 32 |

| #3 | #10 | 0.376 | 0.561 | 0.375 = 3/8“ | 9.525 | 0.11 | 71 |

| #4 | #13 | 0.668 | 0.996 | 0.500 = 1/2“ | 12.7 | 0.20 | 129 |

| #5 | #16 | 1.043 | 1.556 | 0.625 = 5/8“ | 15.875 | 0.31 | 200 |

| #6 | #19 | 1.502 | 2.24 | 0.750 = 3/4“ | 19.05 | 0.44 | 284 |

| #7 | #22 | 2.044 | 3.049 | 0.875 = 7/8“ | 22.225 | 0.60 | 387 |

| #8 | #25 | 2.670 | 3.982 | 1.000 = 1″ | 25.4 | 0.79 | 509 |

| #9 | #29 | 3.400 | 5.071 | 1.128 = 1 1/8“ | 28.65 | 1.00 | 645 |

| #10 | #32 | 4.303 | 6.418 | 1.270 = 1 1/4“ | 32.26 | 1.27 | 819 |

| #11 | #36 | 5.313 | 7.924 | 1.410 = 1 3/8“ | 35.81 | 1.56 | 1006 |

| #14 | #43 | 7.650 | 11.41 | 1.693 = 1 3/4“ | 43 | 2.25 | 1452 |

| #18 | #57 | 13.60 | 20.284 | 2.257 = 2 1/4“ | 57.3 | 4.00 | 2581 |

Canadian Rebar Weight and Dimensions

Canadian rebar sizes and dimensions

| Metric Bar Size | Weight kg/m |

Nominal Diameter mm |

Nominal Area mm2 |

|---|---|---|---|

| 10M | 0.785 | 11.3 | 100 |

| 15M | 1.570 | 16.0 | 200 |

| 20M | 2.355 | 19.5 | 300 |

| 25M | 3.925 | 25.2 | 500 |

| 30M | 5.495 | 29.9 | 700 |

| 35M | 7.850 | 35.7 | 1000 |

| 45M | 11.775 | 43.7 | 1500 |

| 55M | 19.625 | 56.4 | 2500 |

European Rebar Weight and Dimensions

European rebar sizes and dimensions

| Metric Bar Size | Weight kg/m |

Nominal Diameter mm |

Nominal Area mm2 |

|---|---|---|---|

| 6,0 | 0.222 | 6 | 28.3 |

| 8,0 | 0.395 | 8 | 50.3 |

| 10,0 | 0.617 | 10 | 78.5 |

| 12,0 | 0.888 | 12 | 113 |

| 14,0 | 1.21 | 14 | 154 |

| 16,0 | 1.58 | 16 | 201 |

| 20,0 | 2.47 | 20 | 314 |

| 25,0 | 3.85 | 25 | 491 |

| 28,0 | 4.83 | 28 | 616 |

| 32,0 | 6.31 | 32 | 804 |

| 40,0 | 9.86 | 40 | 1257 |

| 50,0 | 15.4 | 50 | 1963 |