Concrete Block Fill Calculator

Find the core fill volume for a concrete block wall and estimate how much grout is required to fill the block using the width and height of a wall or given a number of CMUs to fill.

-

By

FindPros

FindPros connects consumers with professionals in over 600 different categories.

-

Reviewed by

Jacky L.

FindPros connects consumers with professionals in over 600 different categories.

Material Estimate:

Grout Needed

Material Cost

On this page:

How to Find Concrete Block Core Fill Volume

Concrete blocks used for construction, also known as concrete masonry units (CMUs) or cinder blocks, typically have one or two holes or voids known as cells to reduce the weight of the block. These cells are filled with concrete or grout during the installation process to strengthen and reinforce the wall. To estimate how much concrete or grout is needed to fill those cells, you need to find the volume necessary to fill each block, then multiply that by the total number of blocks in the wall.

Step 1: Find the Volume of Each Block Void

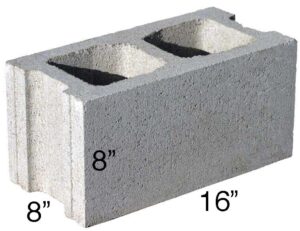

To get the volume of each block, begin by getting its total size in inches. The standard size for a CMU is 8″ x 8″ x 16″, but there are many variations.

Each CMU is made up of two “shells” along the front and back and two to three “webs”, which run from the front to the back of the block. Measure the thickness of each one, then subtract the width of the shells from the width and the width of the webs from the length of each block.

You will also need the number of cells, with two being standard. You will divide the total length by the number of cells. In a block that measures 8″ x 8″ x 16″, this will look like:

Multiply the new width and length by the height of each block to get the cubic inches for that block:

Keep in mind that CMU measurements are nominal, meaning that they are often slightly smaller than their given measurements to account for the mortar between them. You may also have a block with custom web and shell measurements, which can change the total volume.

To get the most accurate volumes, always measure each area on the block yourself, and use those measurements when doing the calculation. Use our volume calculator to simplify this process.

Step 2: Find the Number of Blocks in the Wall

The next step is to find the number of blocks in the wall. This can be done by counting the number of blocks in the wall, or by getting the square footage of the wall and of the block you want to use and dividing the total square footage of the wall by the square footage of the block.

For an 8 x 16 block, this is 0.89 sq ft. Or, use our concrete block calculator to find how many blocks are in your wall.

Step 3: Find the Total Concrete Block Fill Volume

Multiply the cubic inches of volume for one block by the total number of blocks in the wall to get the total volume in cubic inches. Divide the final number by 46,656 to find the volume in cubic yards. A conversion calculator can make this easy.

Fill Volume for Various Block Wall Thicknesses

Below are the average fill volumes needed for a 100-square-foot wall based on the thickness of the wall. Keep in mind that these volumes can change if you are using a block with different web or shell measurements or if you are using a block that is not 8″ x 16″ in face measurements.

| Block Wall Thickness | Blocks Filled per Cubic Yard | Concrete/Grout per 100 Block | Concrete/Grout per 100 Square Feet Wall Area |

|---|---|---|---|

| 6″ | 120 | .83 yd3 | .93 yd3 |

| 8″ | 100 | 1.0 yd3 | 1.12 yd3 |

| 10″ | 80 | 1.23 yd3 | 1.3 yd3 |

| 12″ | 65 | 1.54 yd3 | 1.73 yd3 |

Approximate grout fill volume and coverage for a concrete block wall.

Frequently Asked Questions

In most cases cinder blocks or CMUs do not need to be filled. Adding fill is a process referred to as grouting, and can add considerable strength to a block wall, reducing the likelihood of cracking. However, some experts argue that in cold or freezing climates, fill material can expand or contract causing the blocks to crack over time.

The most commonly used materials to fill the cells or voids in concrete blocks is mortar, concrete, sand, and gravel to add strength. These don’t offer much insulation value, but you can fill the block using insulation.

You will need one cubic yard of fill for every 100 blocks for an 8″ thick wall.