Asphalt Calculator

Estimate the amount of asphalt and base needed for a driveway parking lot, or small road and estimate the price of material using our calculator below.

-

By

FindPros

FindPros connects consumers with professionals in over 600 different categories.

-

Reviewed by

Jacky L.

FindPros connects consumers with professionals in over 600 different categories.

Material Estimate:

Estimated Material Cost:

*Estimate only – costs vary by location/vendor, selected material, and quantities.

Installation Overview:

Learn how we calculated this below

Direct Link to Results:

How to Estimate Asphalt

Asphalt is a cost-effective and attractive option for a driveway or parking lot compared to alternatives, such as concrete, and requires little maintenance. Its dark color gives it an attractive appearance and hides imperfections.

Blacktop is a popular material in the north and areas where freeze/thaw conditions may cause materials like concrete to crack. Asphalt is made of a mixture of aggregates, including sand, crushed stone, or gravel held together with a binder made of bitumen.

Different grades and types of asphalt are available, which can influence things like cost and usage. When preparing for a new driveway, it’s essential to estimate the asphalt and other materials needed and be armed with a realistic labor cost to ensure you get a fair price.

How Much Asphalt Do You Need?

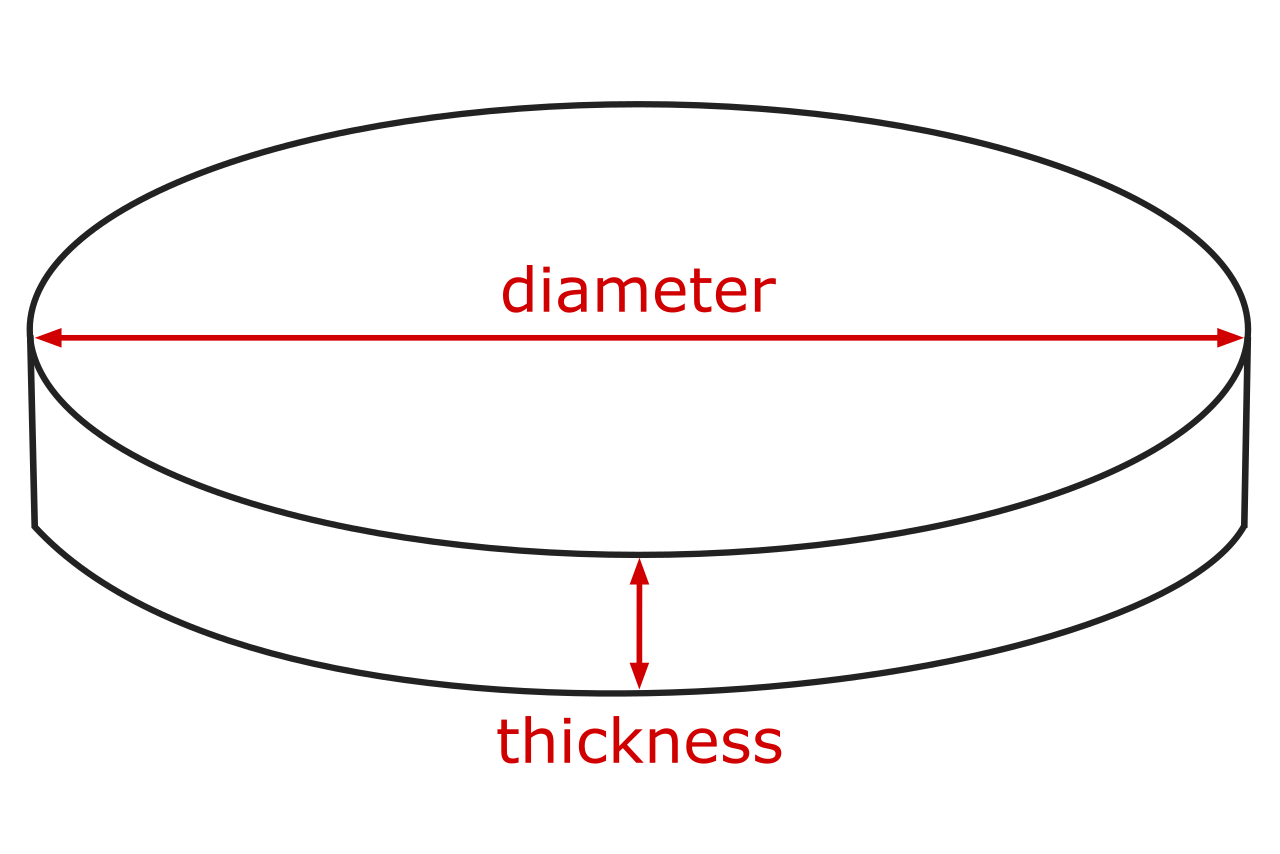

Hot mix asphalt is most often sold by the ton, and coverage varies based on the mix of aggregate and binder. Most asphalt mixes used for driveways and parking lots will weigh 142-148 pounds per cubic foot of coverage, with 145 being the average.

Using this formula, it is possible to find out how much asphalt you’ll need for a project.

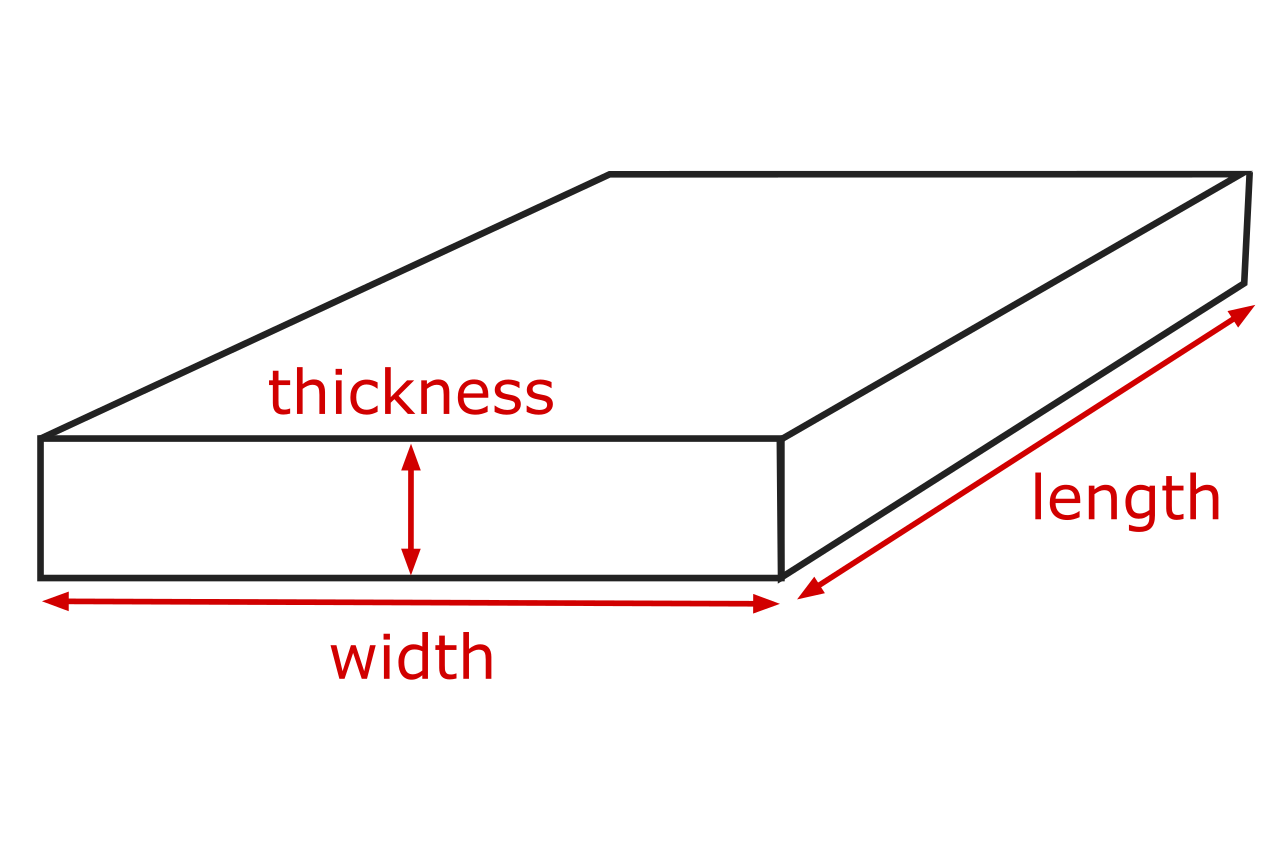

To find the cubic footage of the project, multiply the length by the width by the depth in feet, then by the depth of the asphalt, or just use a cubic footage calculator. For example, 3” of asphalt is equal to 0.25 feet.

For example, a 10′ wide x 20′ long driveway with a depth of 3″ would be 50 cubic feet.

To find the amount of asphalt needed, multiply the cubic footage by 145 to find the total weight needed, then divide by 2,000.

You might also be interested in our asphalt sealer calculator.

Frequently Asked Questions

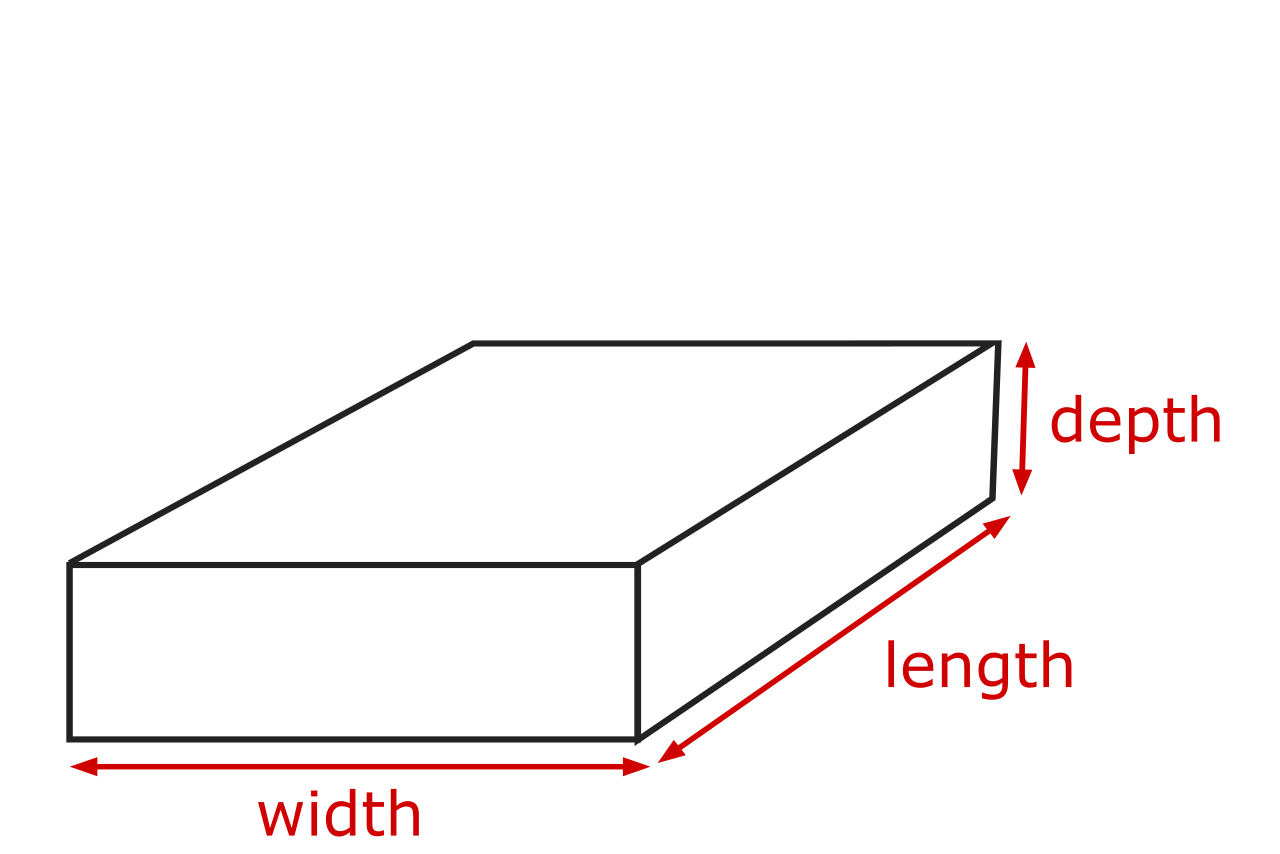

You can install asphalt in different thicknesses, but 3″ is the minimum thickness you should install. Residential driveways should be a minimum of 3″ thick with a 2″ thick base layer of asphalt and a 1″ thick top-wearing surface.

However, in cold climates, it is frequently recommended that you go thicker, using between 4″ and 6″ of full-depth asphalt. This will ensure that your driveway will be less likely to crack or develop frost heaves over time.

Parking lots expecting light-duty usage should be a minimum of 4-5″ thick, while parking lots designed for heavy-duty or truck use should be at least 7-8″ thick.

Most professionals suggest installing asphalt over a base of compacted crushed rock. Residential driveways installed over a sandy surface should have a 4″ compacted crushed gravel base, and driveways installed over clay should have an 8″ compacted crushed gravel base. Parking lots should also have an 8″ crushed gravel base.

Using a base can help you reduce the amount of asphalt needed. A base of crushed gravel that is 4” to 6” deep with a 3” base of asphalt on top can be a good option for many homes and may save over using a full thickness of asphalt.

Asphalt driveways typically cost $4,000 – $8,000 to install, depending on the size, local labor rates, and amount of prep work needed. If you need to remove an existing driveway, the costs could increase. Labor rates vary in different regions, and the overall cost will vary significantly with the cost of labor.